TTI is at the forefront of providing advanced filtration technologies that enable a variety of industries, including oil and gas, to achieve reliable and efficient operations, ensuring optimal performance of their critical equipment and systems.

The equipment and machinery involved in the oil and gas industry relies on the ability to either vertically drill into an underground reservoir well or horizontally drill and frack (also known as hydraulic fracturing) to access stores of oil that were previously inaccessible. New technologies have also allowed the oil and gas industry to do deep underwater drilling to get to more oil than it had access to previously.

Conventional drills rely on large diesel engines that burn diesel-fuel oil to generate electrical power in order to drill into the ground. Fracking involves pumping millions of gallons of chemicals, sand, and water into deep underground to create fissures in the surrounding shale rock to release the gas and oil that are trapped there.

Contaminants such as dirt or debris can work their way into equipment and systems, causing damage and unexpected downtime.

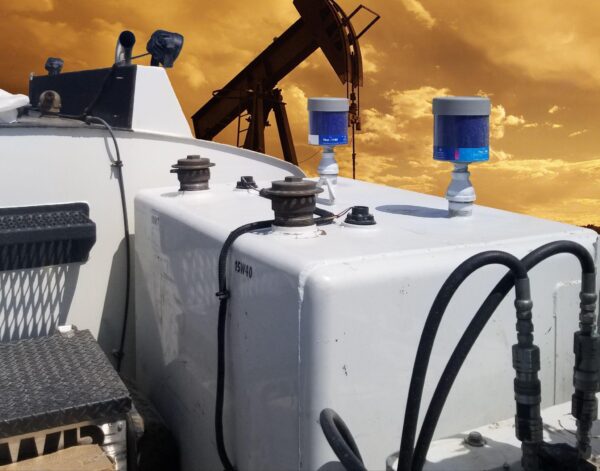

Our hydraulic and lubrication filters, as well as desiccant breathers enable the oil and gas industry to stay productive and run reliably without the worry of unexpected downtime and costly repairs.

TTI’s PowerBreather™ desiccant breathers are multi-tiered devices that are installed on systems and equipment so that it can “breathe”; and are used to prevent external contaminants such as moisture, dirt, and airborne debris from entering reservoirs, gearboxes, totes, and drums throughout the industry. They play a crucial role in maintaining the performance of the oil and gas industry’s machinery by keeping the interior of the equipment and systems clean down to 1-micron absolute with the use of our proprietary, German manufactured, Dual Phase Microglass Media; and dry with the use of our best-in-class silica gel.

Our PowerGuard™ hydraulic and lubrication filters, remove the contaminants from within the oil and gas industry’s systems and equipment with Beta 1000 efficiency, and include media add-on offerings such as water absorptive media, static dissipative media, as well as TTI’s patented SmartFlow™ media technology.

TTI’s product offering is manufactured in our Northglenn, Colorado location, we ship most products in a matter of days and our quality and performance is top-tier. Contact us for more product details and to learn how our wide range of technically-advanced products, including our desiccant breathers and hydraulic and lubrication filters, can protect your system.

https://www.toddtechinc.com/success-stories/titan-smartflow-powerbreather-lasts-twice-as-long/