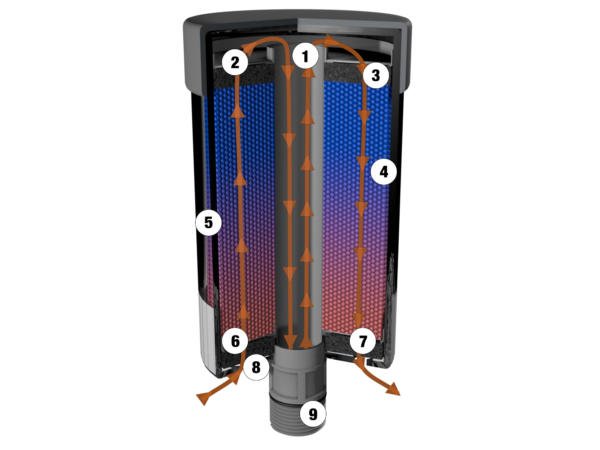

This PowerBreatherTM unit is a marked improvement over the customary dust caps or OEM breathers on equipment. When contaminated air enters the top of power breathers, it passes through layered filter media, preventing solid particles from entering the breather and causing undue wear to your equipment surfaces. Filtered air passes through a bed of PowerBreatherTM (fuel tank breather) silica gel, which removes harmful moisture from the air. The silica beads also work to attract moisture from inside the equipment reservoir during service or shut-down, keeping the equipment dry.

The center tube is constructed from rugged nylon material providing rigidity to the element and allowing for even airflow through the silica gel.

The second filter step prevents any possible migration of silica dust providing added system protection.

Polyurethane foam collects oil mist and distributes air evenly over filter media and moisture absorbing silica gel.

The Power BreatherTM silica gel provides industry leading moisture removal and holds up to 40% of its weight.

Clear outer shell provides a visual indicator of silica gel condition allowing for optimum change out intervals.

3-micron absolute particulate filtration is provided by a polyester filter media.

Polyurethane foam collects oil mist and distributes air evenly over filter media and moisture absorbing silica gel.

Air intakes are opened based on flow requirements and provide moisture protection for breather while being shipped/stored.

Use sure-fit connections instead of filler/breather cap. (Adapters also available)

ABS, Nylon, Polypropylene, Buna

Silica Gel

Polyester, Polyurethane

3-Micron Absolute

-20°F to 200°F (-29°C to 93°C)

The TTI PowerBreatherTM offers significant performance improvements over other leading desiccant breathers.

Multiple head-to-head tests with leading competitors demonstrate that TTI PowerBreatherTM silica gel averages nearly 20% more moisture holding capacity than other leading brands.

The increased body length of the TTI PowerBreatherTM allows for 10% more volume of our silica gel when compared to leading competitors.

| Model | Connection | Height | Width | Max Moisture Retention | Max Airflow at 1 PSID |

| TT-BB | 3/8″ Sure-Fit (NPT,BSPP,BSPT) | 4.14″ (10.52cm) | 2.54″ (6.45cm) | 28 ml (1.0 fl oz) | 7 cfm (198 lpm) |

| TT-1 | 3/8″ Sure-Fit (NPT,BSPP,BSPT) | 5.59″ (14.2cm) | 2.54″ (6.45cm) | 60 ml (2.0 fl oz) | 7 cfm (198 lpm) |

| TT-2 | 1″ Sure-Fit (NPT,BSPP,NPSM) | 6.11″ (15.52cm) | 4.10″ (10.41cm) | 142 ml (4.8 fl oz) | 18 cfm (510 lpm) |

| TT-3 | 1″ Sure-Fit (NPT,BSPP,NPSM) | 8.28″ (21.03cm) | 4.10″ (10.41cm) | 264 ml (8.9 fl oz) | 18 cfm (510 lpm) |

| TT-4 | 1″ Sure-Fit (NPT,BSPP,NPSM) | 10.38″ (26.37cm) | 4.10″ (10.41cm) | 424 ml (14.3 fl oz) | 18 cfm (510 lpm) |

Not sure which desiccant breather model is right for your system? Try our sizing tool to find the best solution for you.

If you have a competitor product number, we can find the right part for you