High flow, extended life PowerBreathers™️ are ideal for tank farms and large applications and can prevent damage to the hydraulic components of equipment. Options include: standard check-valve technology, SmartFlow™ technology, and no check-valve option for extreme flow applications. These breather designs are great for all types of manufacturing equipment, in all types of environments and application requirements.

The Standard check-valve hydraulic reservoir breather model offers protection from ambient humidity in intermittent operations.

The no check-valve reservoir breather model offers extremely high flows at reduced pressure drops for large applications.

| Standard Model | Europe | Connection | Height | Width | Max Airflow at 1 PSID | Max Moisture Retention |

| Titan-600 | Titan-600E | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 4.4″ | 5.7″ | 27 cfm (765 lpm) | 272 ml (9.2 fl oz) |

| Titan-1100 | Titan-1100E | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 6.5″ | 5.7″ | 26 cfm (736 lpm) | 500 ml (16.9 fl oz) |

| Titan-1600 | Titan-1600E | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 8.6″ | 5.7″ | 25 cfm (708 lpm) | 728 ml (24.6 fl oz) |

| Titan-2100 | Titan-2100E | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 10.7″ | 5.7″ | 24 cfm (680 lpm) | 958 ml (32.4 fl oz) |

| No Check-Valve | Europe | Connection | Height | Width | Max Airflow at 1 PSID | Max Moisture Retention |

| Titan-600-NC | Titan-600E-NC | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 4.4″ | 5.7″ | 39 cfm (1104 lpm) | 272 ml (9.2 fl oz) |

| Titan-1100-NC | Titan-1100E-NC | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 6.5″ | 5.7″ | 36 cfm (1019 lpm) | 500 ml (16.9 fl oz) |

| Titan-1600-NC | Titan-1600E-NC | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 8.6″ | 5.7″ | 35 cfm (991 lpm) | 728 ml (24.6 fl oz) |

| Titan-2100-NC | Titan-2100E-NC | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 10.7″ | 5.7″ | 32 cfm (906 lpm) | 958 ml (32.4 fl oz) |

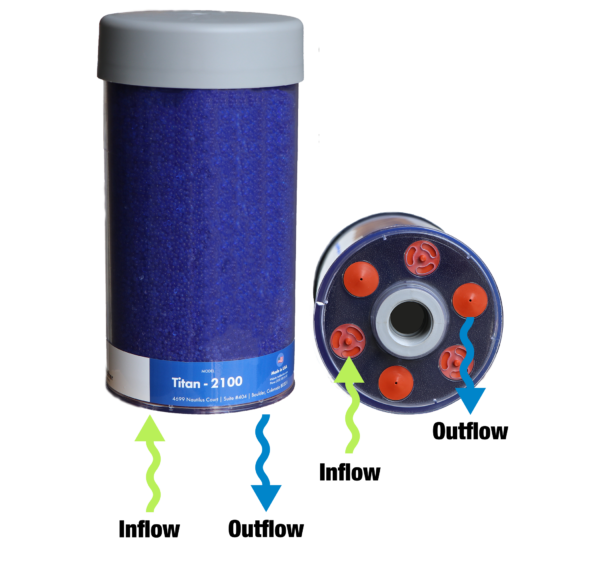

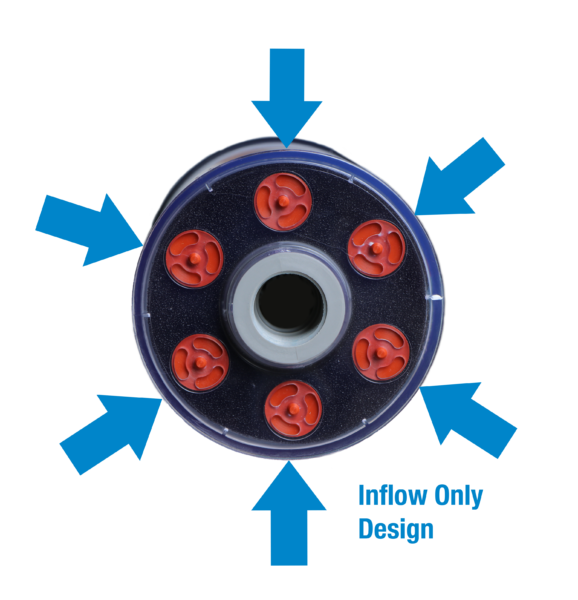

The SmartFlow™️ adapter has a quintessential air flow design, allowing for exhaust of the outflow air prior to entering the reservoir breather. This protects the desiccant filter breather from oil mist and system humidity, resulting in longer breather life.

Titan SmartFlowTM PowerBreathersTM (Titan-XXXX-SF) consist of all check valves positioned inward to exclusively inhale from the atmosphere, therefore must be used with the Titan-SF-A1 (1″ FNPT) or Titan-SF-A2 (2″ FNPT) SmartFlowTM Adapters to exhale all air out of the system.

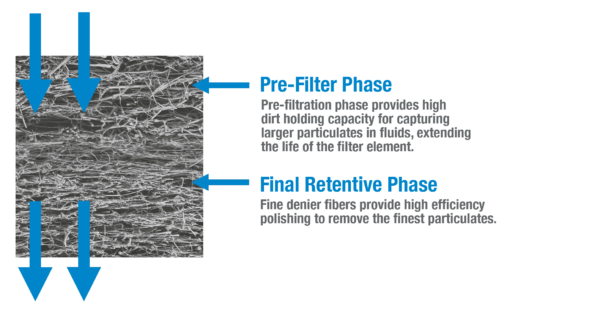

Delivers superior filtration efficiency, dirt holding capacity and low pressure drop.

Pre-filtration layer provides high-capacity capture of bulk airborne particulates.

Fine denier fibers provide high-efficiency polishing to remove the finest particulate

| SmartFlowTM Model | Europe | Connection | Height | Width | Max Airflow at 1 PSID | Max Moisture Retention |

| Titan-600-SF | Titan-600E-SF | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 4.4″ | 5.7″ | 30 cfm (845 lpm) | 272 ml (9.2 fl oz) |

| Titan-1100-SF | Titan-1100E-SF | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 6.5″ | 5.7″ | 29 cfm (821 lpm) | 500 ml (16.9 fl oz) |

| Titan-1600-SF | Titan-1600E-SF | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 8.6″ | 5.7″ | 28 cfm (793 lpm) | 728 ml (24.6 fl oz) |

| Titan-2100-SF | Titan-2100E-SF | 1″ Sure-Fit (FNPT, FBSPP, FNPSM) | 10.7″ | 5.7″ | 26 cfm (736 lpm) | 958 ml (32.4 fl oz) |

Not sure which desiccant breather model is right for your system? Try our sizing tool to find the best solution for you.

If you have a competitor product number, we can find the right part for you

Utilizing TTI power breather technology helps prevent particulate contamination and component failure, even in harsh environments. From extended service life to preventing harmful contamination levels, utilizing TTI technology can do wonders at giving your hydraulic systems a longer service life.

To learn about the Titan PowerBreather™️/ Reservoir Breather technology we offer at TTI, as well as our wide range of products for industrial applications and hydraulic system applications, give our customer service team a call today at 303-585-0132 or complete our contact form.