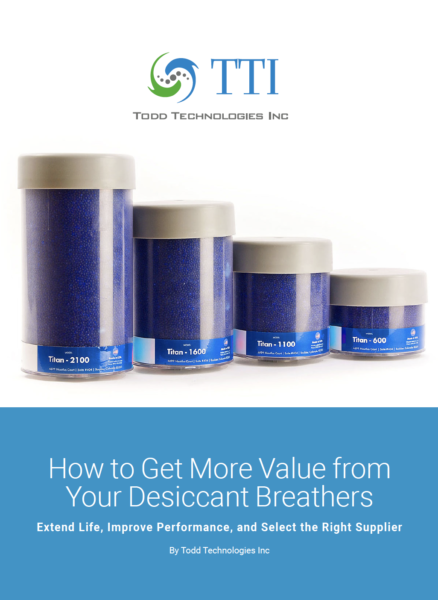

The frequency of replacement or servicing of desiccant breathers will vary depending on the operating environment, the cleanliness levels required, and the specific desiccant breather model used.

As industrial machinery becomes more complex, the importance of proper maintenance and filtration becomes increasingly critical.

Our informative article details how to deal with moisture contamination inside of lubricants and machines.

Our informative white paper details how desiccant breathers work, how to choose the right one, how to install one and more!

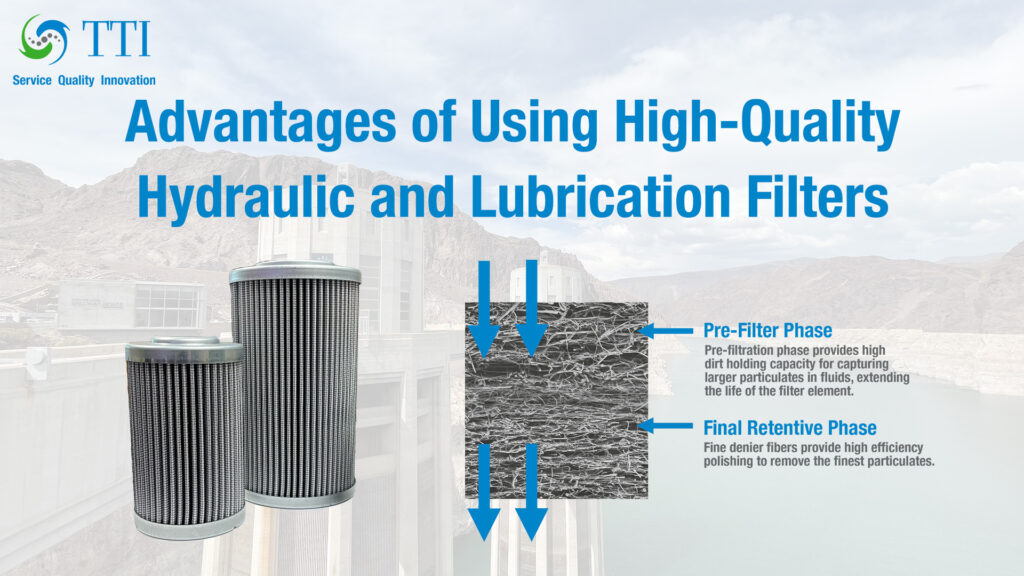

Our informative white paper details how to extend life, improve performance and selecting the right supplier.

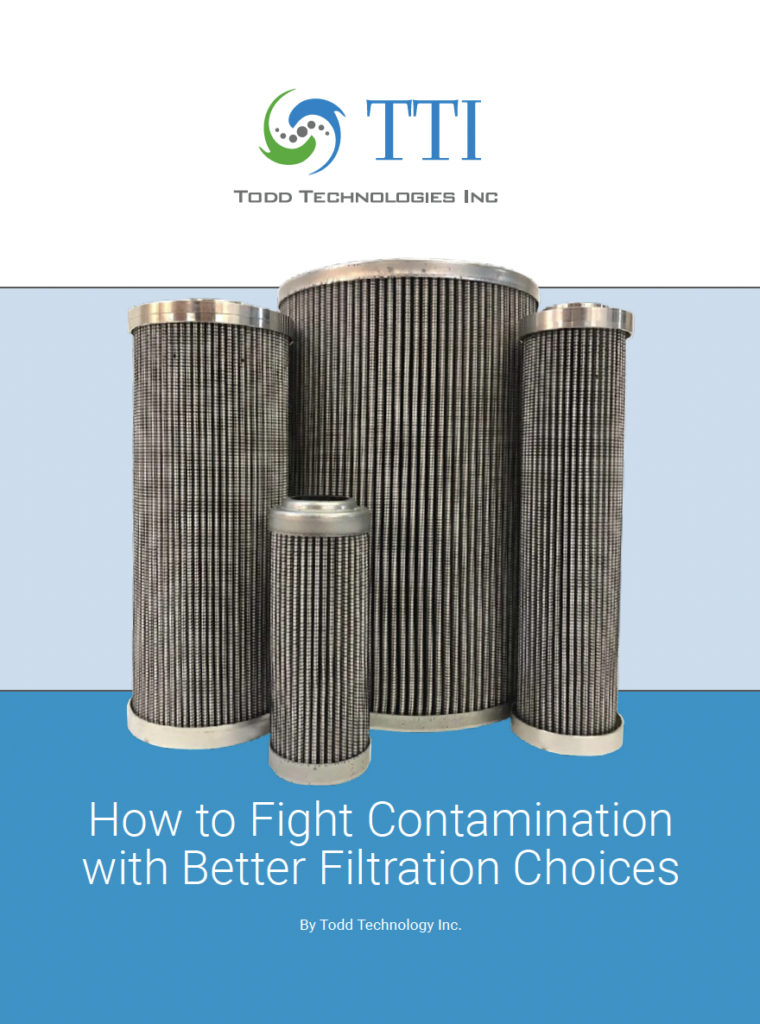

Our informative white paper details how to mitigate or avoid problems that stem from particle contamination and reduce the total cost of machine ownership.

Our informative article details best filtration practices for reducing contaminant buildup, enhancing component service life, and trimming maintenance costs.

Our informative article reviews filter failure detection and prevention while implementing best practices.

Our informative article reviews valuable filtration questions to ask when optimizing machine performance.

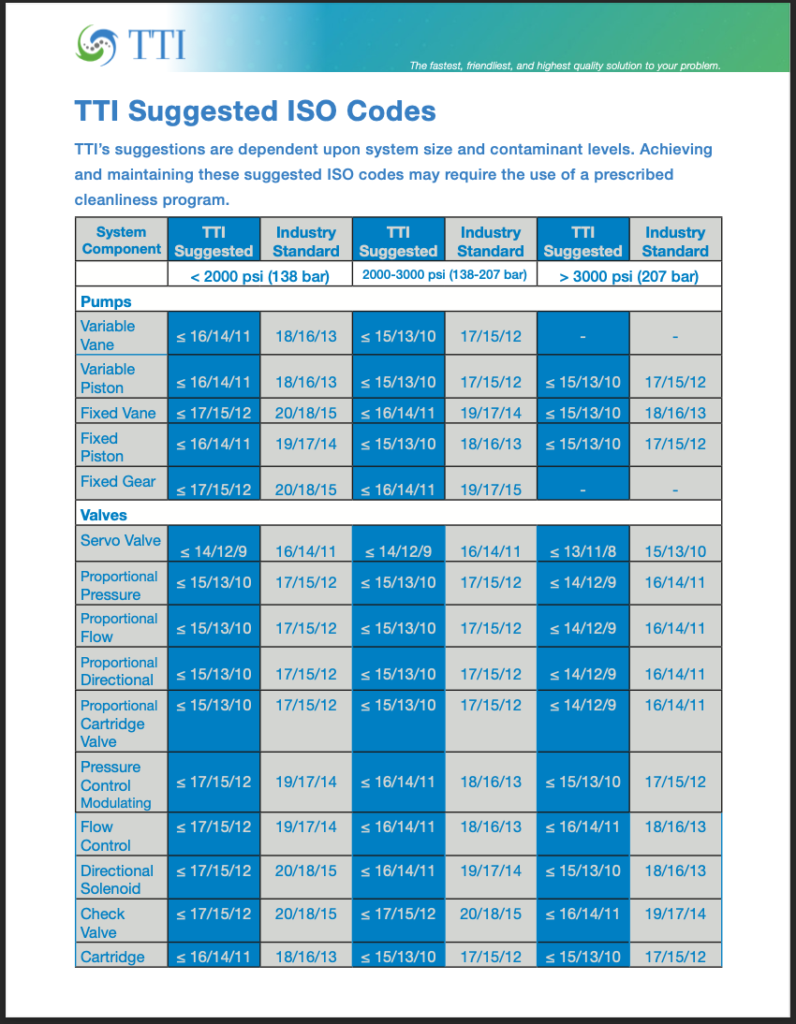

Knowledge is power, and understanding where specific components in your system should be operating is important.

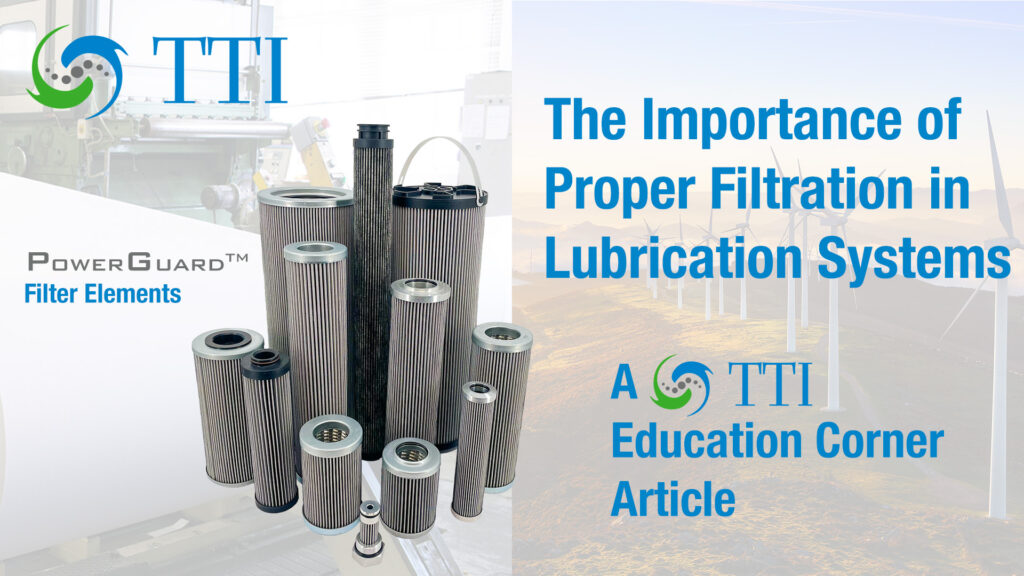

Proper filtration inside of lubrication systems is the key to longevity and preventing unexpected downtime.

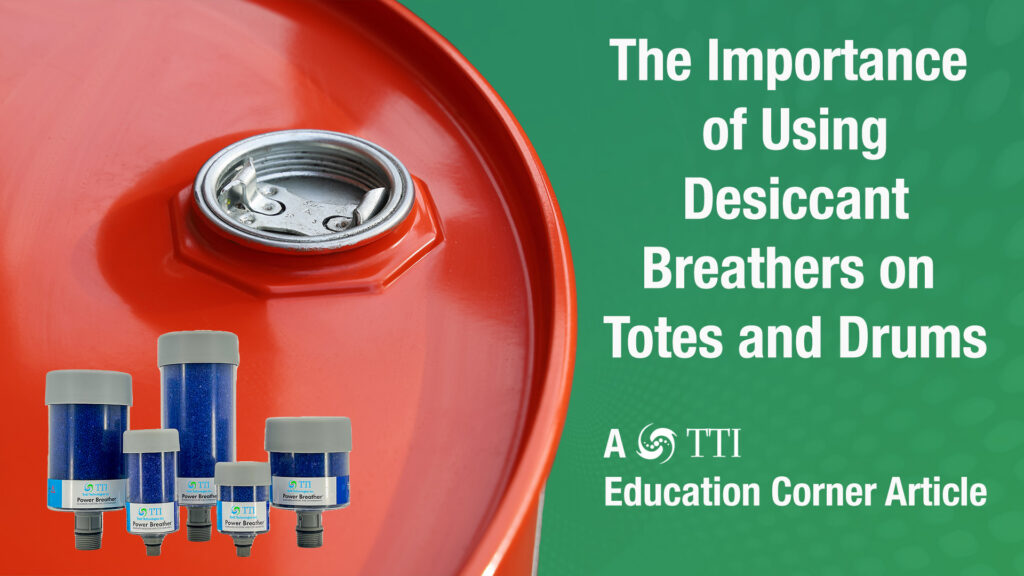

Totes and drums store the most important parts of our hydraulic, lubrication, or fuel systems. Therefore, it is only right to protect them the best you can.

High-quality hydraulic and lubrication filters are an essential component of industrial equipment and system maintenance.

Desiccant breathers are a vital component in ensuring the longevity and efficiency of industrial equipment and systems.

Poor filtration inside of hydraulic and lubrication equipment and systems can lead to several problems that can negatively impact performance, safety, and cost.

A detailed explanation of hydraulic tank breathers and their necessity. Exploring their purpose, benefits, and potential issues that can arise from their absence.

When it comes to operating machinery and equipment, one of the most important factors in maintaining reliable performance is doing predictive maintenance. Learn more.

Discover the inner workings of desiccant breathers and learn how they protect equipment from moisture and contaminants.

Learn why oil reservoir tanks need moisture and particulate protection in this short Education Corner Article.

Filtration is a critical aspect of many industrial processes, especially those involving hydraulic and lubrication systems. Poor filtration has a significant impact on equipment performance resulting in higher maintenance costs, reduced efficiency, and shorter lifespan.