A TTI client in the energy services sector was looking to increase the service life of their breathers in several applications, including a Serva model Twin Fluid Pump.

Industry: Energy services sector

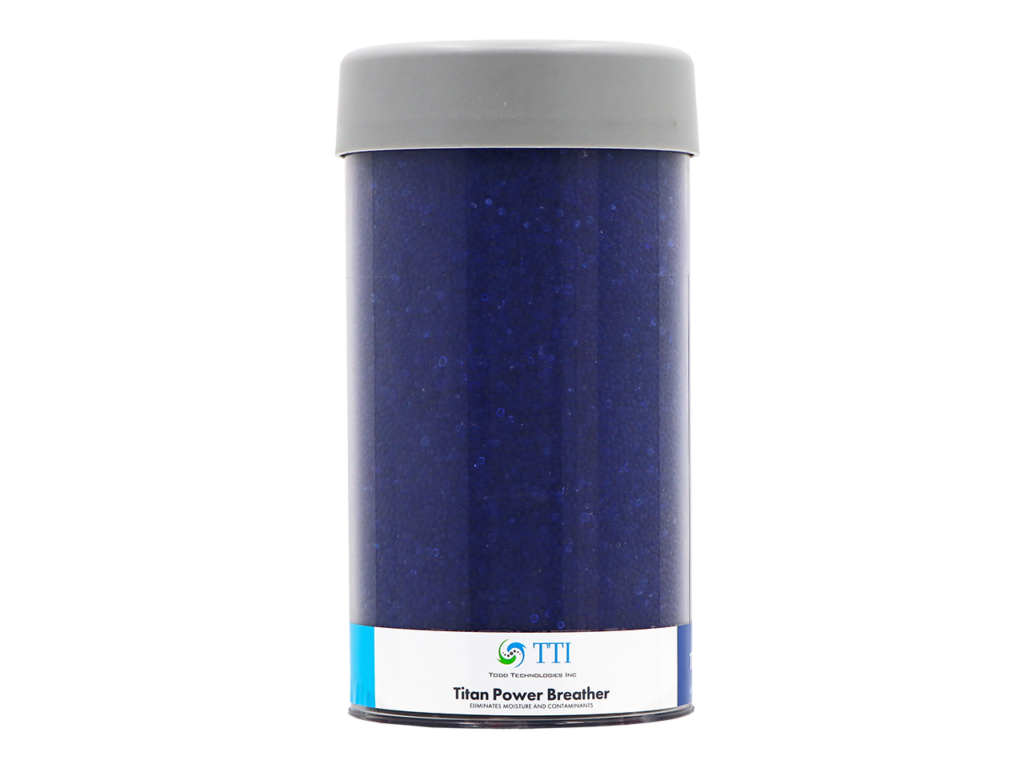

Products Used: TTI Titan Power Breather Line

A TTI client in the energy services sector was looking to increase the service life of their breathers in several applications, including a Serva model Twin Fluid Pump.

Serva pump was outfitted with two desiccant breathers—one on the passenger’s side and one on the driver’s side of the machine. The client had previously used other desiccant breathers but was looking at new supplier options to find a better fit for their application.

In discussing the issue, the client reported that competing breathers had typically lasted 500 to 1000 service hours before needing replacement. They were looking for a solution to extend the service life of breathers and asked TTI to help select a better option for their application.

After discussing the applications, the client decided to use TTI’s Titan 1100 on the driver side and a Titan 2100 on the passenger side of the machine.

Two breathers were in place for over 6 months and accumulated 1602 hours of service over that period. The Titan 2100 on the passenger side could have been utilized longer, but the decision was made to switch both out as the unit was down for service at the time.

By the end of the test, the Titan 1100 on the driver side had completely changed color to pink and was due for change. The Titan 2100 was changing to pink at the top but the bottom was still mostly blue (breathers are shown upside down on a bench to the right).

When desiccant color changes from the top down in this way, it likely indicates a higher humidity condition on the inside of the machine. So in this case, the breather was primarily doing the job of drying out the inside of the machine itself rather than the incoming air.

This is a great example of how getting to know your breathers leads to a better understanding of your machine and its needs. Learning more

about breathers and tracking their change intervals can even help alert you of machine failure, but more on that in a bit.

While it is difficult to quantify the lifespan of desiccant filters without strict control over ambient temperature and relative humidity, both the smaller 1100 model and larger 2100 model significantly outlasted the competition in this application, providing from 37.5% up to as high as 70% greater service life. As described above, choosing proper sizing for each application is one of the keys to success. The TTI Titan 2100 breather still had service life left at the end of the test period, a testament to its longevity.

By optimizing their breather and supplier selection the client was able to achieve their goal. They reported, “The Titan Power Breathers are performing well. Versus leading competitors we used previously, they are offering greater longevity.”

In the end, the client was very pleased with the performance of their new breathers and the partnership they formed with TTI in the process. Both proper breather size selection and proper hardware options (such as check valves) helped drive this success. TTI’s industry-leading Power Gel also plays a major role.

“The Titan Power Breathers are performing well. Versus leading competitors we used previously, they are offering greater longevity.“

– A TTI Client in the Energy Sector