A White Paper Published by Noria

Desiccant breathers remove contaminants such as dirt and moisture from air entering machinery, sumps and reservoirs. Below we discuss how desiccant breathers work, how to choose the right one, how to install one and more.

Desiccant Breathers Design and Construction

Desiccant Breather Installation

Next Level Breather Technology

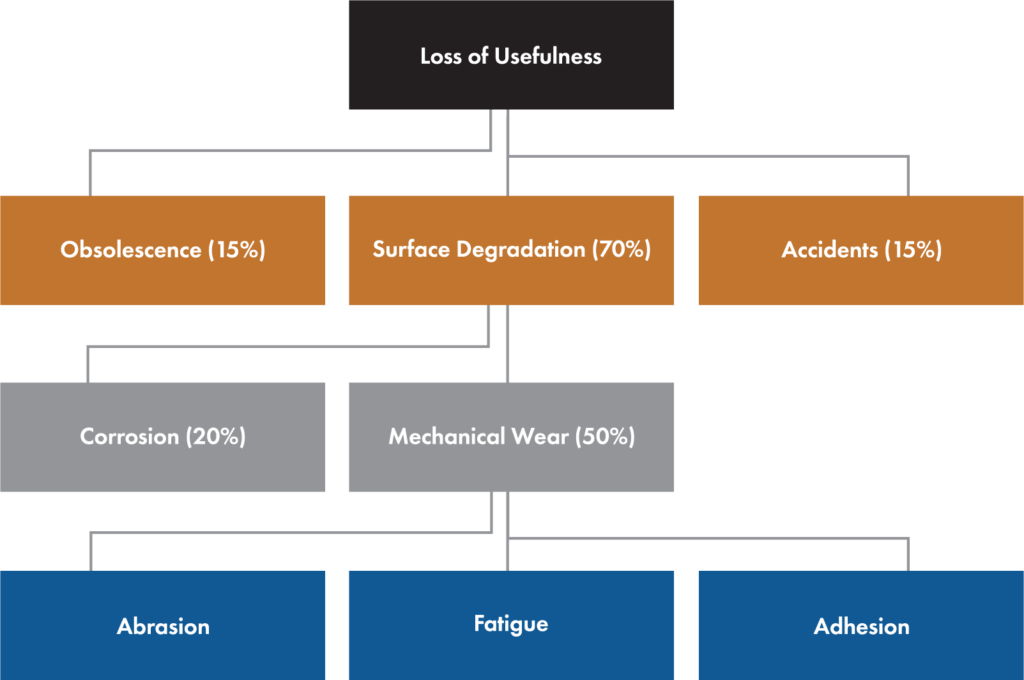

Studies have shown that around 70% of equipment or machinery loss of use is due to surface degradation. Of that 70%, 20% of replacements are a direct result of corrosion and the other 50% are due to mechanical wear. The most common causes of this corrosion and mechanical wear are dirt and moisture originating outside the machine. When you have moisture in your lubricant or hydraulic fluid, a myriad of negative effects start occurring. For example, moisture leads to corrosion, which in turn leads to particulate contamination. Moisture can also change oil viscosity, deplete additives and cause sludge formation.

Before we can define a desiccant breather, we need to understand what a desiccant is. A desiccant is defined as a hygroscopic substance (material that attracts and holds water molecules) that induces or sustains a state of dryness in its vicinity. Have you ever opened a box of new shoes or a packet of beef jerky and seen those little packets labeled “do not eat”? Those packets contain silica gel, which is a desiccant. Other types of desiccants are used as well.

Desiccant breathers are multi-tiered devices installed on your machines to prevent the entry of two crucial contaminants: moisture and particles. Equipment like gearboxes, pumps and reservoirs must “breathe” when air in the headspace expands and contracts due to temperature changes and oil level changes in the case of hydraulic systems, incoming fluid displaces air or when hydraulic components are working. Each time equipment “breathes,” dirt, debris and moisture are brought in, contaminating the lubricant and damaging the equipment over time. Since we know at least half of lubricant contamination comes from outside machinery and most machines are designed to “breathe,” it’s a good idea to stop these contaminants at the source. Enter desiccant breathers.

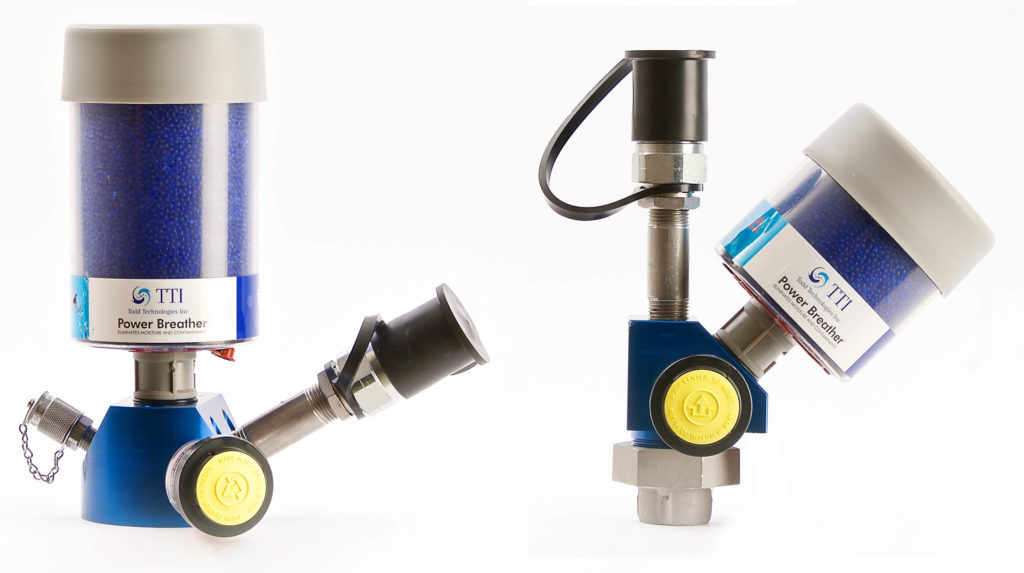

Some, like our line of desiccant Power Breathers at TTI, work by using a three-stage design to help ensure the interior of your equipment stays clean and dry. Incoming air is cleaned and dehydrated through an initial solid particle filter, a container of silica gel and another solid particle filter.

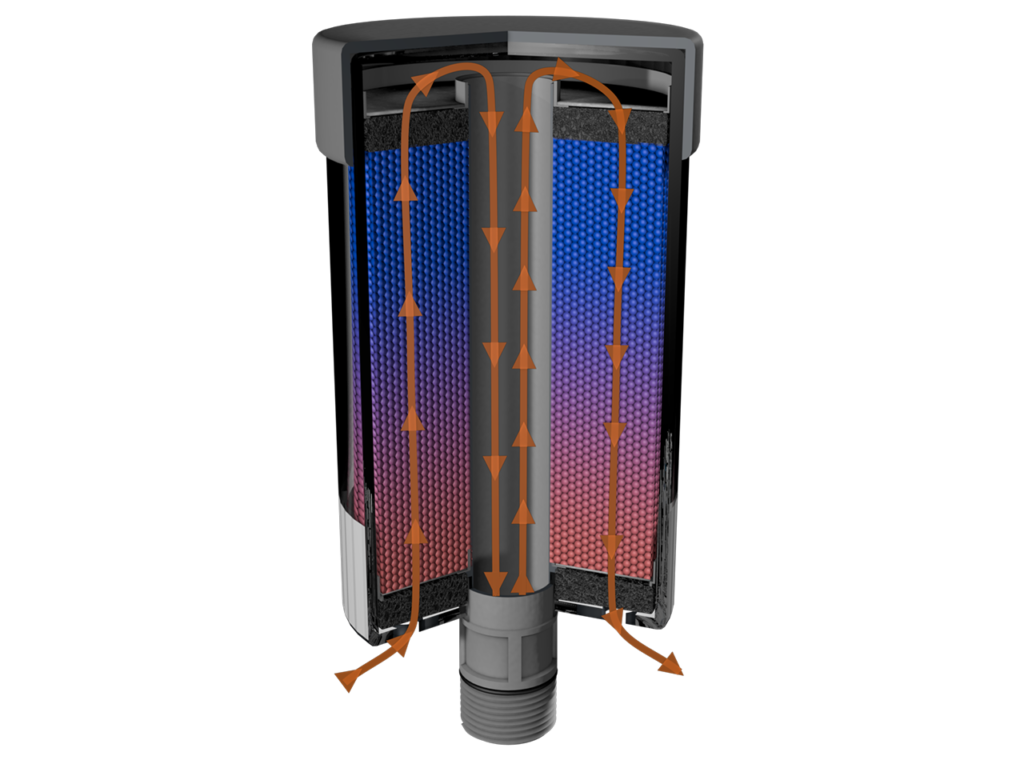

At TTI, we use Dual Phase microglass media in several of our consumable and Rebuildable Power Breathers to offer industry-leading dirt holding capacity in your breather. As our diagram shows, desiccant breathers work like this:

As the machine exhales, air travels through the desiccant breather in reverse, or may purge directly to the atmosphere depending on the breather’s design. As the breather’s silica gel becomes absorbed with moisture, it turns a different color. Color varies depending on the brand of desiccant breather, but at TTI, the US Power Breather line starts blue and turns pink when saturated. This is how you’ll know it’s hydrated and time to replace the desiccant. Many desiccant breather models implement components to help extend the life of the breather. Our foam poly urethane layer on the bottom of the breather absorbs any oil vapor or oil splashing up that could get into the silica gel of the desiccant breather, shortening its lifespan. In addition, our TTI Power Breather-CV uses check valves to help extend the life of the desiccant by providing a closed system until airflow is needed. In other words, using a desiccant breather with an intake check valve allows airflow into the breather only when the differential pressure between the atmosphere and fluid reservoir exceed a certain threshold.

In addition to the standard-style Power Breather and Power Breather CV (check valve) options, other add-ons you see may include:

A common question that comes up when discussing how desiccant breathers work is how long do they last? Most breathers last anywhere from three to six months if properly sized. The answer depends on four variables:

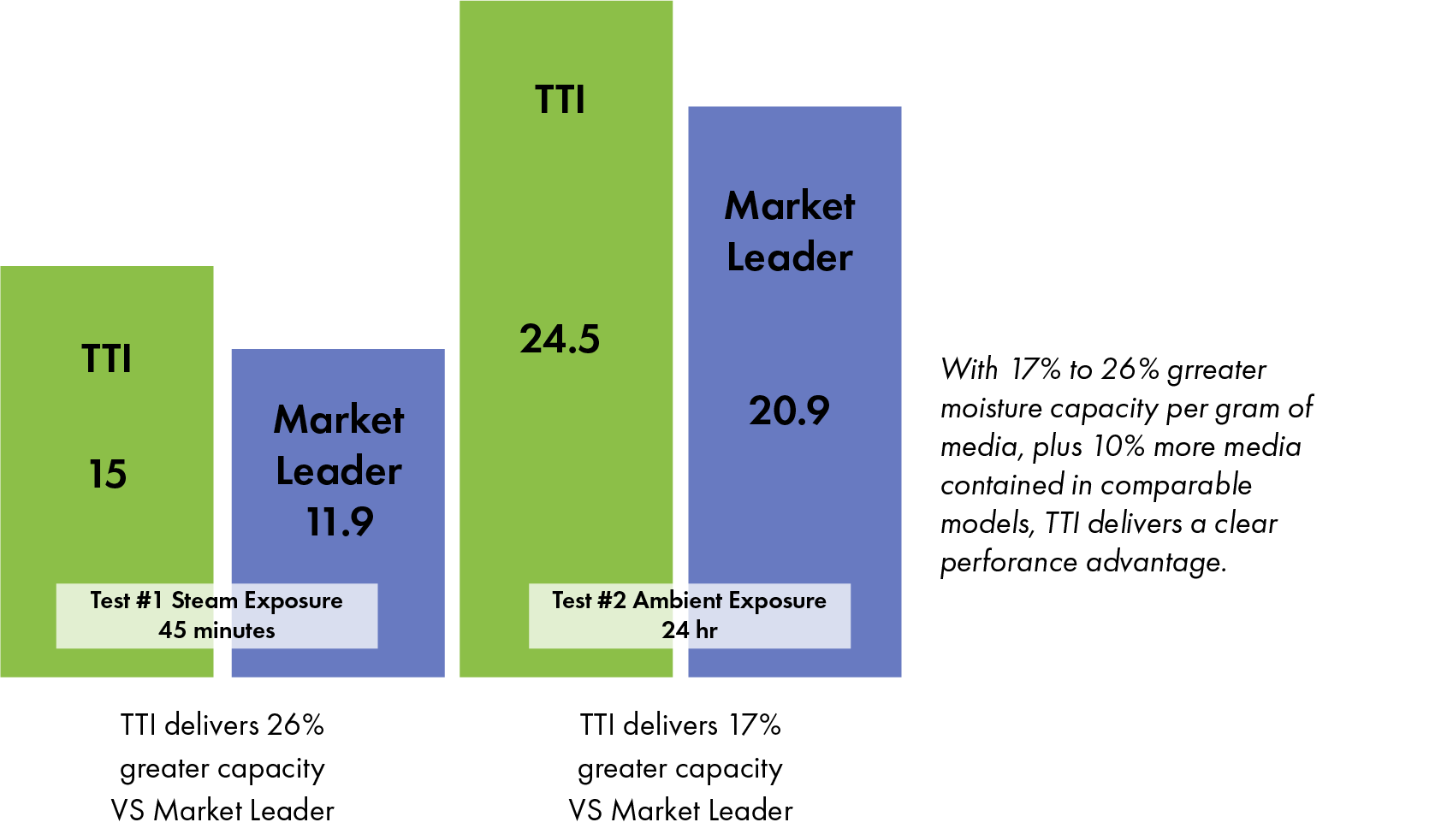

Intake frequency and volume of breathing refers to how much moist air passes through the breather. Each time a piece of equipment breathes, water vapor is retained in the silica gel, gradually shortening the life of the breather. The amount of water the breather can hold directly relates to the amount of silica gel in the breather. Most desiccant breather manufacturers have a chart with the maximum water capacity for each breather, so you’ll know how much moisture the breather can retain before reaching the end of its life. At TTI, we use industry-leading power gel with greater moisture-holding capacity, offering an average of 20% greater lifespan over the competition.

Humid work environments tend to shorten the lifespan of a desiccant breather. As the humidity increases, the silica gel reaches its maximum moisture-holding capacity faster. Once this capacity is reached, no more moisture can be removed from incoming air, meaning it is time to replace your breather.

Your machine’s operating environment should be considered as it pertains to the amount of contamination. For example, severe environments like those with water spray or large amounts of dirt should use a desiccant breather that can hold higher amounts of ambient contamination. Severe environments might require breathers with check valves to help prolong their lives.

The application refers to the type of equipment needing a desiccant breather or the type of work being done. At TTI, our models come in multiple sizes and in a series, to cater to your application (what machinery you have or the kind of plant you’re operating in). Typical application categories can be broken down as follows:

One of the most important factors to consider when looking at desiccant breathers is your airflow rate. Desiccant breathers are sized according to the required cubic feet per minute (CFM). Always choose a breather with a higher CFM capacity than the CFM requirements of your tank or reservoir. Installing a desiccant breather without enough airflow and creates excessive pressure causing a vacuum which will damage the pumps and other system components. It is very important the breather doesn’t restrict air to the point it creates implosion within the system. If you need to convert gallons per minute (GPM) to CFM, the breather manufacturer should have the corresponding GPM/CFM numbers for your reference.

The capacity of the reservoir often impacts how quickly the desiccant may be saturated with moisture. More oil equals more humidity in most cases. Reservoir capacity is also important to consider because the bigger the reservoir, the more headspace fluctuation there might be, which affects the amount of air moving through the breather. Each breather model has different reservoir capacity requirements, so it’s important to check the breather model number for specifics on the amount of cfm air flow capacity going to the reservoir before making your final purchase.

Lastly, desiccant breathers are rated for either continuous or intermittent flow. This is usually important when deciding between our standard Power Breather or Power Breather CV option. In intermittent flows, our Power Breather CV options will help extend the life of the breather.

The desiccant breather replaces your machine’s breather cap. Installing a desiccant breather is a straightforward and simple process, especially since many breather models are screw-on installation types. At TTI, our offerings can turn-key replace industry-leading offerings in a wide array of sizes and configurations.

Our line of adapter kits also allows you to install breathers on various types of equipment with the ability to seamlessly fill system fluid and sample fluid health, all while leaving the breather in place. Examples of available adapter kits include:

As previously discussed, contamination from dirt, dust and particularly moisture enters equipment and machinery as it “breathes.” Water-contaminated oil leads to additive depletion, oil oxidation, and rust and corrosion over time, shortening the life of your machinery. TTI’s Power Breathers mitigate moisture and debris, greatly reducing contamination and prolonging the life of machines and equipment. There are many real-world examples of how installing a TTI desiccant Power Breather saves companies money by shortening the frequency of downtime and keeping equipment contamination free.

Pick the breather with the greatest efficiency and lifespan.

TTI is the best choice in market for breather spend. Controlling maintenance spend is more important now than ever, and TTI delivers superior value to market over leading competitors.

Head-to-head trials have proven that TTI Power Breathers offer on average 20% more life than leading competitors. This ultimately results in lower reduced maintenance and labor costs and lowers annual breather spend in both unit and freight cost.

TTI offers its industry leading Power Gel and revolutionary Dual Phase microglass media in several consumable and rebuildable Power Breather options. Our expansive product offerings allowing for customers to choose the best fit for their application.

Time is important, and with TTI desiccant Power Breathers, plant maintenance professionals will save significant annual time in breather change-out and upkeep.

Our product quality compares favorably vs all our competitors (large and small). Our desiccant line is directly interchangeable with both Des-Case and Air Sentry, and offers 20–25% greater performance.

Our products range allows us to offer solutions to problem applications in a wide variety of industries.

We offer excellent price points, coupled with our outstanding product performance making us the best overall value in the industry.

Our customers truly enjoy working with us. We are timely in our responses and do what we say that we will do.

We invite end users to bring us their most challenging applications. We have the ability and are willing to customize products to fit specific customer needs.

Typically a fraction of the competition. We measure in 1-3 days, our competition measures in weeks – this is extremely valuable.