Ensure optimal system performance, longevity, and cleanliness with products engineered for the Steel Manufacturing Industry.

In the metals manufacturing industry, quality filtration is essential for maintaining equipment reliability, minimizing downtime, and extending the lifespan of critical systems such as hydraulic and lubrication equipment. These applications operate under high pressures, temperatures, and humidity, making them especially vulnerable to damage from contaminants.

Common contaminants:

Systems at Risk:

Implementing high-performance filtration helps ensure cleaner fluids, more efficient operation, and lower maintenance costs across the board.

TTI’s proprietary DuoGlass media ensures industry-leading filtration efficiency and greater dirt holding capacity — resulting in cleaner systems, smoother operations, and extended life for both components and overall assets.

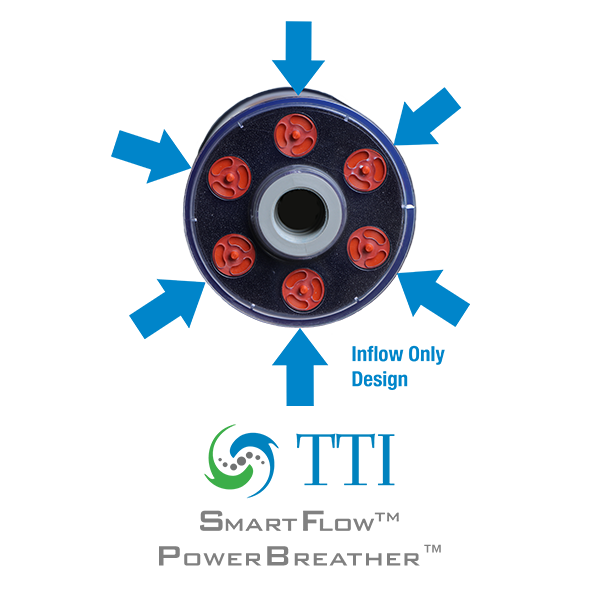

Experience up to 35% longer service life compared to competing filtration products. With fewer changeouts and less downtime, PowerGuard filters and PowerBreathers offer greater maintenance efficiency and long-term cost savings.

SmartMedia filter elements allow multiple medias to work together in a single element, delivering 35% longer filter lifespan, broader contaminant protection, and lower differential pressure to prevent sparking — all while maintaining desired system cleanliness and filtration efficiency.

At TTI, we’re never content with the status quo. From proprietary medias and patented technologies to next-generation breather upgrades, we’re continuously pushing boundaries to offer higher value and more effective solutions to meet the evolving demands of the global power industry

Not sure which desiccant breather model is right for your system? Try our sizing tool to find the best solution for you.

If you have a competitor product number, we can find the right part for you.

To learn more about our extensive range of products and how we can meet your equipment needs and reduce maintenance costs, please call us today at 303-585-0132 or leave a message through our contact form.