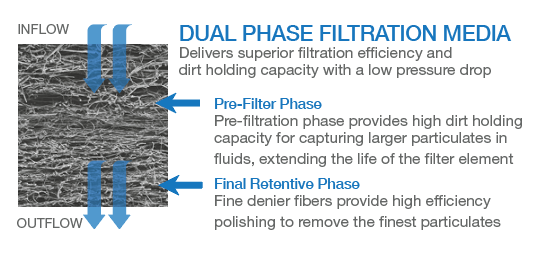

TTI has exclusively chosen Dual Phase microglass media as our standard for the entire TTI product line. The Dual Phase microglass media is produced on state-of-the-art automated wet laid production equipment which offers unparalleled quality control and custom capabilities for hard-to-solve filtration applications.

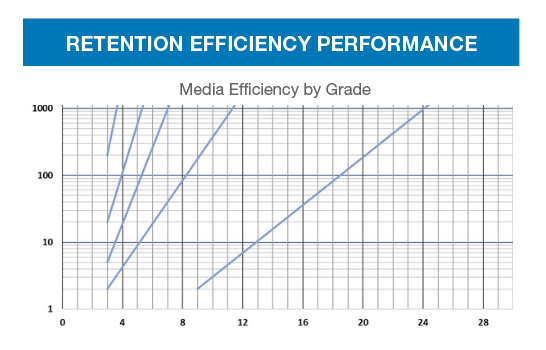

Filters used in hydraulic or lubrication systems are tasked with reducing particulate contamination to a targeted level of cleanliness over the service life of the element. The ISO 4406 standard presents a means of specifying these goals by way of a universal cleanliness code. The table below reflects our knowledge and experience designing elements and should be considered a starting point as to what you can expect from your system using the selected TTI microglass media. Your performance can vary based on flow rate, viscosity, differential pressure, and contamination level. It is recommended to conduct trials to verify your filtration process meets your performance goals.

Our dual phase microglass is available in ratings of 1μm, 3μm, 6μm,10μm, and 25μm, with high dirt holding capacity and low pressure drop.

Tested according to ISO 16889 (multi-pass test). Valid up to 50 psi differential pressure.